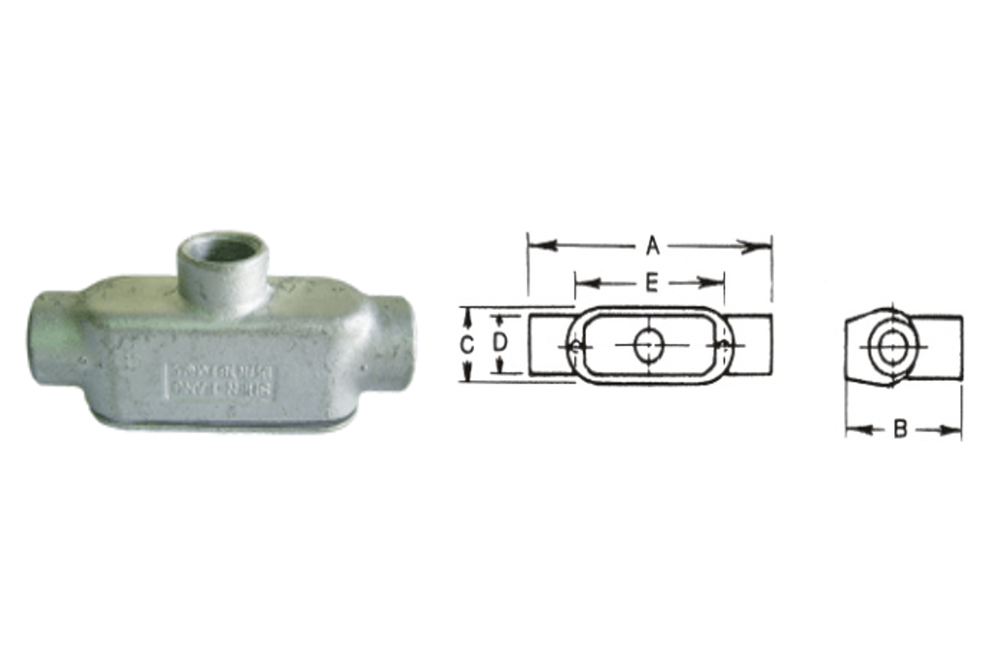

TB TYPE - CONDUIT OUTLET BODIES

A conduit body can be used to provide pulling access in a run of conduit, to allow more bends to be made in a particular section of conduit, to conserve space where a full size bend radius would be impractical or impossible, or to split a conduit path into multiple directions. Conductors may not be spliced inside a conduit body, unless it is specifically listed for such use.More over, Malleable-Iron types feature built-in pulling rollers that help prevent damage when cables are pulled through hubs. Flat-back models provide greater cubic content for easier wire pulling, and additional room for splicing. Fit flush and snug against flat surfaces for stable installation.

UL List E Number : E 493318 (安全增防爆)

According to NEC Articles 501.10(b), this fitting is suitable for use in Class I ,Divison 2

單位:±3mm

|

規格 |

鑄鐵 Cast Iron |

可鍛鑄鐵 Malleable Iron 球墨鑄鐵 Ductile Iron |

表面處理 |

鑄不銹鋼CF8 Stainless Steel (SUS304,316) |

鋁合金 |

尺寸 Dimensions |

||||

|

型號 |

型號 |

型號 |

型號 |

A |

B |

C |

D |

E |

||

|

1/2 |

TB 16 |

TB 16-M |

電鍍鋅 達克銹 Dacrotizing |

TB 16-S |

TB 16-A |

146 |

52 |

30 |

32 |

92 |

|

3/4 |

TB 22 |

TB 22-M |

TB 22-S |

TB 22-A |

150 |

60 |

40 |

38 |

98 |

|

|

1 |

TB 28 |

TB 28-M |

TB 28-S |

TB 28-A |

181 |

71 |

47 |

44 |

116 |

|

|

1 1/4 |

TB 36 |

TB 36-M |

TB 36-S |

TB 36-A |

220 |

95 |

59 |

54 |

144 |

|

|

1 1/2 |

TB 42 |

TB 42-M |

TB 42-S |

TB 42-A |

242 |

96 |

67 |

61 |

165 |

|

|

2 |

TB 54 |

TB 54-M |

TB 54-S |

TB 54-A |

275 |

110 |

82 |

75 |

190 |

|

|

2 1/2 |

TB 70 |

TB 70-M |

TB 70-S |

TB 70-A |

325 |

145 |

104 |

93 |

223 |

|

|

3 |

TB 82 |

TB 82-M |

TB 82-S |

TB 82-A |

375 |

160 |

115 |

108 |

263 |

|

|

4 |

TB104 |

TB104-M |

TB104-S |

TB104-A |

476 |

205 |

164 |

132 |

341 |

|

Standard Materials :

Cast Iron

Ductile Iron

Malleable Iron

Aluminum

SUS 304

SUS 316

Standard Finishes :

Hot Dip Galvanizing

Electroplated with Zinc

1.Our Conduit bodies' features are smooth, and rounded integral bushings in hubs will protect conductor insulation.

2. Accurately tapped, tapered threads for tight, rigid joints and excellent ground continuity.

3. Conduit bodies with cast covers and gasket are suitable for use in wet locations.

4. Conduit bodies can provide installed conductors with pull outlets

5. Flat back design provides greater cubic content for easier wire pulling, and more room for splicing. Fits flush and snug against flat surfaces for more stable installation.

6. Conduit bodies can allow conduit runs to bend 90 degree.

7. Smooth hub bushings and cover openings protect conductor insulation. Smooth hub openings allow easy conduit joining.

8. Hub size, body style, compliance data, maximum wire number/ size and cubic capacity molded into body.

9. Conduit Bodies are supplied with threaded hubs for use with rigid or IMC pipe or as a joint body.